World-Class OEE

What Is World-Class OEE?

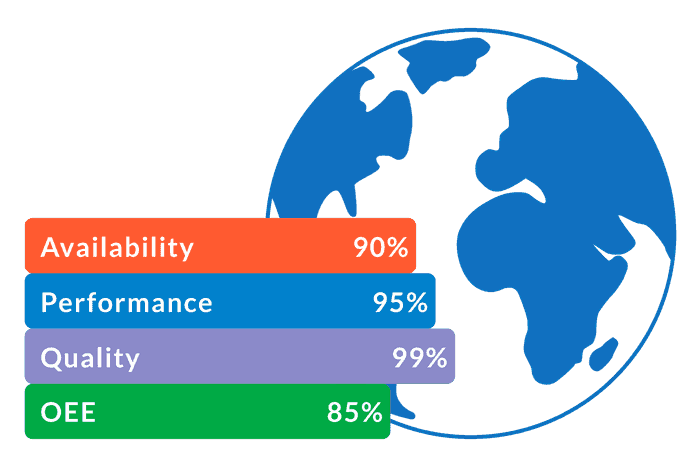

OEE is the ratio of Fully Productive Time to Planned Production Time (refer to the OEE Factors page for a graphical representation). It is calculated as the product of its three constituent factors:

OEE = Availability × Performance × Quality

The nature of this calculation makes achieving a high OEE score quite challenging. For example, if all three factors are 90%, the resultant OEE will only be 73%.

In practice, the generally accepted world-class goals for each factor are quite different from each other, as is shown in the image below. Note that these figures apply to discrete manufacturing (as opposed to process industries).

TPM and World-Class OEE

People often ask – where do these World-Class OEE numbers come from?

The answer is simple. Seiichi Nakajima led the introduction of TPM, OEE and the Six Big Losses in the early 1970s while at the Japanese Institute of Plant Maintenance. In his 1984 book, Introduction to TPM (translated to English and published in 1988 by Productivity Press), Seiichi Nakajima included the above four “world-class” numbers.

Seiichi defined these numbers, based on his practical experience, as minimums for which companies should strive. He also noted that all of the companies winning the Distinguished Plant Prize, awarded annually in Japan to plants that had successfully implemented TPM, had OEE scores in excess of 85%.

Some Perspective on World-Class OEE

The World-Class OEE figures are interesting and useful, but keep in mind that they have roots in a particular place (Japan), at a particular time (1970s), and in a particular industry (automotive).

The reality is that most manufacturing companies, even today, have OEE scores closer to 60%. We work with thousands of manufacturing companies, and we see more companies with OEE scores lower than 45% than companies with OEE scores higher than 85%.

The important point is – don’t fixate on the absolute value of the number. Fixate on your ability to improve that number.

Even within a manufacturing plant it can be counterproductive to set just one OEE target. For example, if you have two identical production lines but one line makes a single product and the other line makes 10 different products would you expect them to have the same OEE score? No. The line making 10 different products is likely to experience far greater Availability Loss due to Changeovers and thus a lower OEE score.

Here is another perspective:

- If your OEE is below 40% – is an 85% target going to motivate your team?

- If your OEE is already 85% – do you really want to stop there?

How to Set an OEE Target

So how should you go about setting an OEE target?

Here is the bottom line. Set an OEE target that will drive solid, incremental improvement for your process. Each OEE target should be a stretch target that is truly achievable, preferably within three or four months.

Also, do your best to avoid comparing dissimilar processes and external OEE benchmarks. There is only one target that really matters: the target that will drive improvement for your process.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.