Visual OEE™

What Is Visual OEE™?

Traditionally, OEE is used as a “rearview mirror” metric. Here is a common scenario:

- During the shift, operators capture Downtime and production counts on a whiteboard or hourly log sheet.

- After the shift, an administrator or supervisor collates the data and generates an OEE report, often as an Excel spreadsheet.

- The next day, the data is reviewed as part of the daily production meeting.

Unfortunately, this method of using information is not timely enough to drive meaningful and proactive improvement on the plant floor. Furthermore, experience has proven that manual data capture frequently suffers from serious accuracy issues (such as significant underreporting of Downtime).

Visual OEE™ brings the benefits of the Visual Factory to OEE. The core idea is to automate data capture, calculate OEE and Six Big Losses in real-time, and also communicate losses in real-time so the plant floor team knows exactly how well they are doing during the shift (we call it “winning the shift”) AND so they can use tools such as SIC (Short Interval Control) to drive improvement during the shift.

Drive Plant Floor Improvement

Truth is – we don’t actually recommend OEE for the plant floor. OEE is a bit too abstract for truly driving improvement on the plant floor. What we do recommend is providing loss information in real-time to engage operators in proactive improvement.

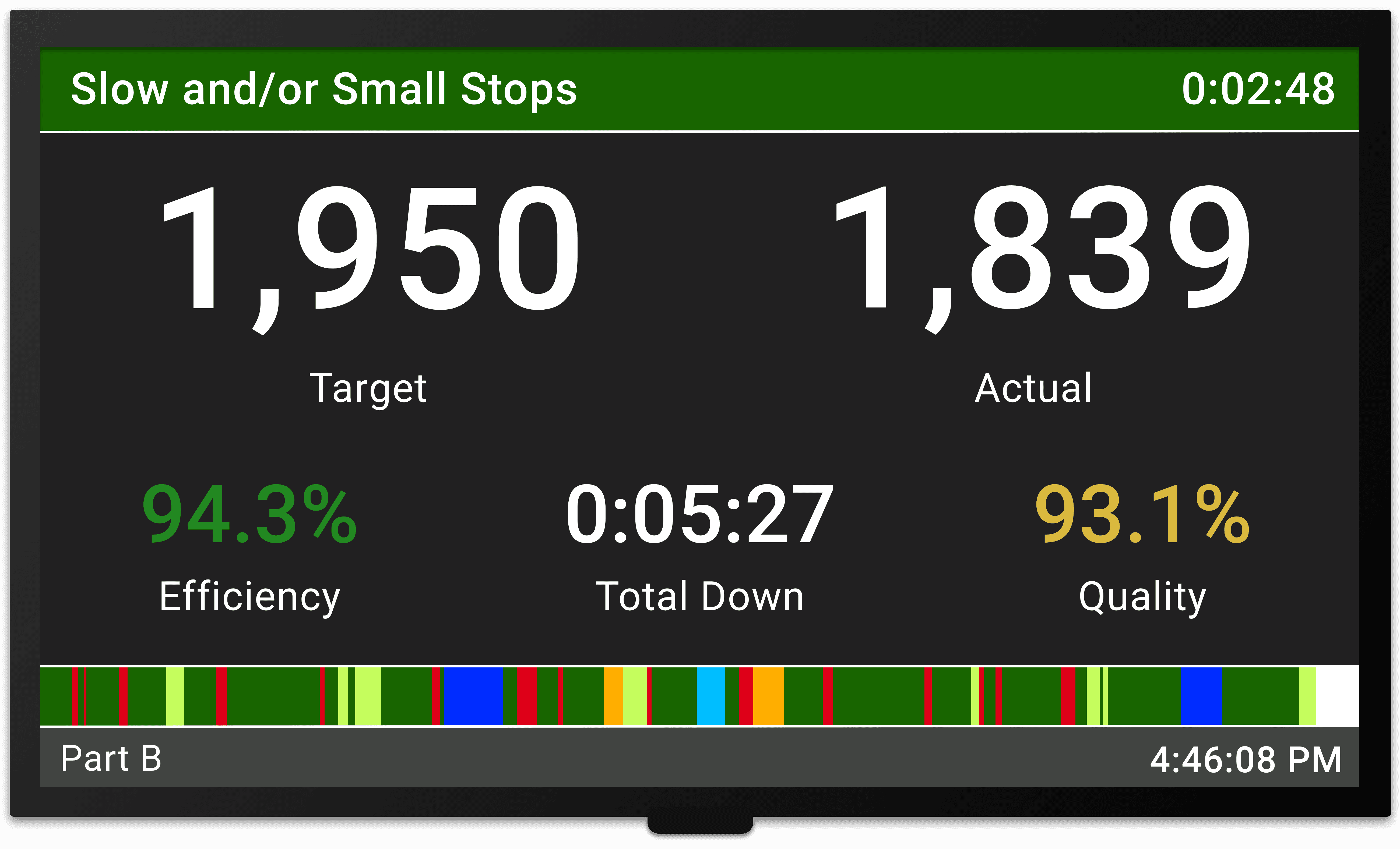

The same information used to capture OEE and Six Big Loss metrics can be used to generate a highly effective set of plant floor metrics that make it super simple for employees to see at any time if they are “winning the shift”. We recommend the following metrics for the plant floor:

- Target: expected good parts

- Actual: actual good parts

- Efficiency: ratio of Actual to Target; 100% or better is “winning the shift”

- Downtime: for most companies the largest and most visible loss

TAED (Target, Actual, Efficiency, Downtime) is simple and effective – and it is fully compatible with measuring OEE and the Six Big Losses. All you need to do is provide Takt Time (a cycle time number that represents the pace of production that aligns production with customer demand).

So in summary:

- Use TAED to motivate operators to win their shift (operational metrics)

- Use Six Big Losses to understand your losses (tactical metrics)

- Use OEE to track improvement over time (strategic metrics)

Build an Information Foundation

A rich and accurate set of information is the foundation for making smart and informed decisions. Fortunately, it is surprisingly easy to automate the collection of production data and build a strong information foundation.

Specifically, with two sensors, an Ideal Cycle Time (required for any calculation of OEE), and a work schedule (to establish Planned Production Time) all of the following information can be generated. Recommended KPIs are shown in bold.

| Metrics | One Sensor | Two Sensors | Ideal Cycle Time |

|---|---|---|---|

| OEE | Availability, Availability Loss, Availability Lost Time, Availability Lost Count | Quality, Quality Loss, Quality Lost Time, Quality Lost Count | OEE, Fully Productive Time, Total Loss, Total Lost Time, Total Lost Count, Performance, Performance Loss, Performance Lost Time, Performance Lost Count |

| Six Big Losses | Unplanned Stop Loss, Unplanned Stop Lost Time, Unplanned Stop Lost Count, Planned Stop Loss, Planned Stop Lost Time, Planned Stop Lost Count | Startup Reject Loss, Startup Reject Lost Time, Startup Reject Lost Count, Production Reject Loss, Production Reject Lost Time, Production Reject Lost Count | Cycle Loss, Cycle Lost Time, Cycle Lost Count, Small Stop Loss, Small Stop Lost Time, Small Stop Lost Count |

| TEEP | TEEP, Utilization, Capacity Loss, Capacity Lost Time | ||

| Counts | Total Count | ||

| Rates | Current Total Rate, Average Total Rate | Current Good Rate, Average Good Rate, Current Reject Rate, Average Reject Rate | |

| Times and Cycles | Run Time, Unplanned Stop Time, Planned Stop Time, Not Scheduled Time, Percent Run, Percent Unplanned Stop, Percent Planned Stop, Run Occurrences, Unplanned Stop Occurrences, Planned Stop Occurrences, Remaining Time, Expected Changeover Time, Actual Changeover Time, MTBF, MTTR | Standard Cycles, Slow Cycles, Small Stops, Total Cycles, Standard Cycle Time, Slow Cycle Time, Small Stop Time, Standard Cycle Lost Time, Slow Cycle Lost Time, Small Stop Lost Time, Current Cycle Time, Previous Cycle Time, Average Cycle Time, Average Standard Cycle Time, Average Slow Cycle Time, Average Small Stop Time |

If you provide just one more number, Takt Time, you can add the following target-based metrics to your information foundation and provide real-time TAED to the plant floor:

| Metrics | Takt Time |

|---|---|

| Target | Efficiency, Percent Variance, Time Variance, Count Variance, Target Count, Target Cycles, Pace Timer, Average Takt Time, Takt Compliance Time, Takt Overage Time, Takt Compliance Percent, Takt Overage Percent |

Manufacturing Improvement Made Easy

Once your information foundation is in place there are many ways to use that information to drive improvement. The three most popular methodologies are Lean Manufacturing, Six Sigma, and Theory of Constraints. All of these methodologies have a great deal to offer for manufacturing improvement. None of these methodologies are easy.

As a result, we are often asked – is there a way we can get started while we put a comprehensive program in place? The answer is yes. We encourage you to look at our Improving OEE page for a simple yet highly effective way to get started.

Vorne Can Help

Are you interested in monitoring and improving your manufacturing process? Having better information about your OEE losses? Are you frustrated by not having the information you need to take effective action?

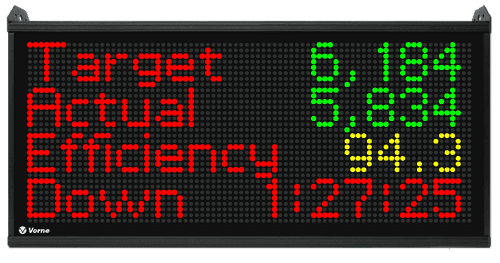

This website is created and maintained by Vorne. We are experts in manufacturing improvement and we are passionate about helping companies achieve results. Our XL Productivity Appliance is an inexpensive, off-the-shelf product that can easily help you achieve everything on this page - and a whole lot more. XL has been deployed on over 35,000 manufacturing processes across 45+ countries.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.