Takt Time

What is Takt Time?

Takt time is a tool for setting the pace and rhythm of your manufacturing process and aligning it with customer demand. As a metric, takt time is the amount of time “budgeted” to manufacture each part, such as producing one part every 22 seconds. As a tool, it helps you to establish flow and eliminate waste in your process.

Takt Time Formula

Takt Time is traditionally calculated from Available Production Time and Customer Demand:

Takt Time is equal to Available Production Time divided by Customer Demand.

In other words, take the amount of production time you have available for running your process, which by convention includes budgeted downtime and excludes changeovers and breaks, and divide that time by the number of pieces you need to manufacture to meet customer demand in order to determine how much time you have to manufacture each piece.

At first glance, this calculation seems simplistic and counterintuitive. Doesn’t your manufacturing process dictate the time it takes to manufacture one piece?

We will explore this question in a moment. But first, recognize that there is a lot of nuance in calculating takt time. It is not a magic number that on its own leads to improved production. Instead, think of it as a tool that will help you promote flow throughout your manufacturing process and reduce waste by balancing the line (so each step moves at the same pace). We will explore all of this and much more in this article.

How is Takt Time Used?

Let’s look at four different ways in which takt time integrates with your manufacturing operations.

1. Capacity Planning

Capacity planning determines how much production capacity you need to meet customer demand. You can think of it as comparing:

- Takt Time: The pace that exactly meets customer demand given available production time. This is a customer-focused metric.

- Operable Takt Time: The pace you can actually achieve with your current process and equipment. This is a manufacturing-focused metric.

Any discrepancy between the two will lead to a suboptimal result: either unmet customer demand or excessive inventory. So, in a perfect world, you want the two to be aligned. Assuming that customer demand is fixed, there are two ways to bring takt time and operable takt time into alignment: change available production time (through production scheduling) or change operable takt time (through process design).

2. Process Design

Process design enables you to align takt time and operable takt time by changing the operable takt time of your process (i.e., the pace you can actually achieve with your current process and equipment). This is typically a medium to long-term strategy. Change operable takt time incrementally by making changes to your existing process or more substantially by modifying the design of your equipment.

3. Production Scheduling

Production scheduling enables you to align takt time and operable takt time by changing the takt time of your process. This is typically a short to medium-term strategy. If customer demand is treated as fixed, the only lever available for changing takt time is available production time. A key strategy is to utilize production scheduling to change available time directly (e.g., through shift schedules) or indirectly (through changing the number of people working at the process).

4. Plant Floor Operations

Plant floor operations are where takt time is transformed from concept to practice. In lean manufacturing terms, it is the place of “gemba” (i.e., the actual spot or scene). There are important nuances to consider when applying takt time to the plant floor.

The first point to consider is whether or not takt time should be interpreted as a strict pace that is not to be exceeded (hint: for most manufacturers, the answer is “no”). Unless you need to constrain pace due to design limitations, such as to control defects, operable takt time should be considered an improvable metric.

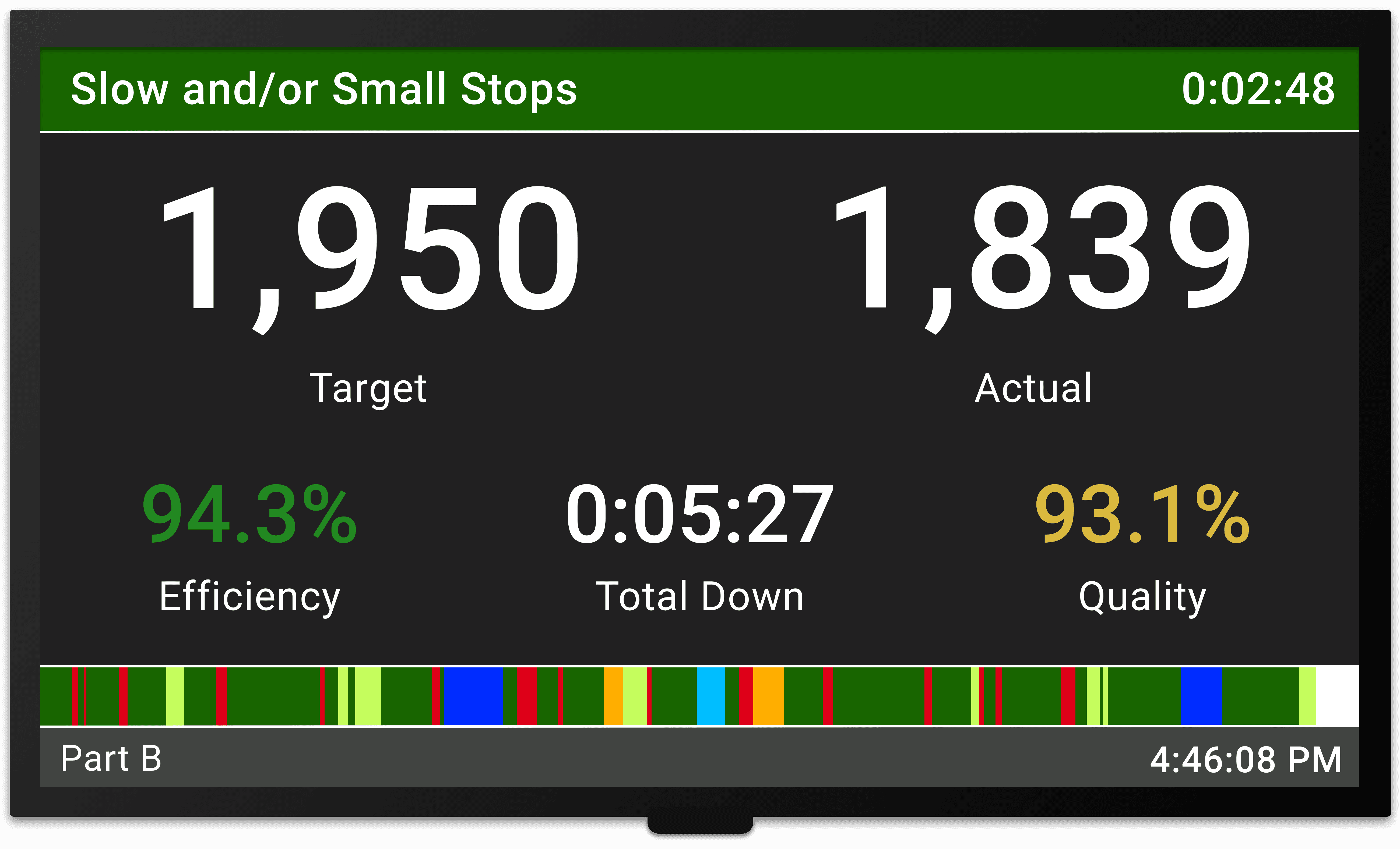

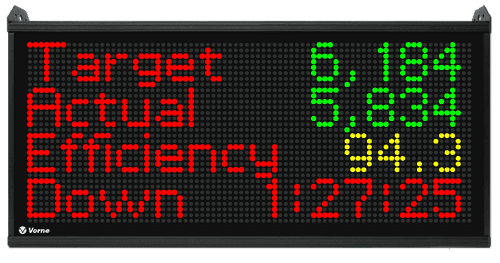

The second point to consider is the best way to translate takt time into something concrete for operators. We recommend TAED: Target, Actual, Efficiency, Downtime, where the target is based on operable takt time. Target is a dynamic value that lets operators know where they should be right now. Unlike a static goal, target is always relevant. The beauty of TAED is that it transforms takt time into an opportunity for operators to “win the shift.”

Learn more about Four Ways to Leverage Takt Time for Your Manufacturing Process.

Why is Takt Time Important?

Manufacturing to the rhythm set by takt time is one of the core principles of lean manufacturing. Takt time provides a meaningful benchmark that you can apply to each step of the manufacturing process, which makes it easier to balance your line (to a specific target) and ensure there is a continuous flow (across steps).

In other words, rather than designing the manufacturing process to run as quickly as possible, the strategy is to design it to run at a consistent, sustainable rate that meets demand with minimal waste.

Takt Time Benefits

Leveraging takt time effectively provides a broad range of benefits, especially since it impacts so many aspects of your manufacturing operations. The benefits of manufacturing to takt include:

- Reducing WIP and inventory

- Providing a foundation for value stream mapping

- Helping to identify and expose bottlenecks

- Making it easier to develop standard work routines

- Improving capacity planning

- Providing a data-centric basis for scheduling

- Providing a real-time target for operators to “win the shift”

In summary, takt time helps to ensure customer demand is met while encouraging the elimination of bottlenecks and other inefficiencies on the production line.

| Aspect | Traditional Manufacturing | Manufacturing to Takt |

|---|---|---|

| Pace | Each step operates as fast as possible with limited coordination between steps. | Each step works at the pace set by takt time, aiming for the same production pace. |

| Result | Bottlenecks, buildup of inventory, and many other forms of waste. | Smooth and consistent flow with little to no waste. |

What Are the Origins of Takt Time?

Who invented takt time? What are its origins? There are two parts to this story.

The story begins in Germany after World War I. Takt is a German word with a literal translation of time, rhythm, cadence, or cycle. In the 1920s, Hugo Junkers implemented Takte (cycle intervals) to deliver aircraft subassemblies to the main process branch exactly when needed. During WWII, Junkers' Taktsystem (timing system) was adopted by Luftwaffe Chief of Procurement Ernst Udet, who standardized it across Germany. For example, Henschel und Sohn used takt stations (pictured below) to pace production of the Tiger I tank, with each takt taking six hours.

As a side note: Simultaneously and independently, Ford Motor Company implemented its own style of flow production at the Willow Run plant in the USA, producing B-24 bombers with a synchronized, rhythmic production line running at a pace of 63 minutes per plane (more or less producing one B-24 per hour).

The takt story continues in Japan during World War II when Junkers' engineers were invited by Mitsubishi to lecture on takt time and continuous flow principles. Then, after the war, Toyota’s CEO Kiichiro Toyoda recruited engineers from the aircraft industry to blend their small batch, continuous flow techniques with Ford’s mass production techniques.

Taiichi Ohno’s Definition of Takt Time

Taiichi Ohno, often referred to as the father of the Toyota Production System (TPS), provided his own definition of takt time:

Toyota Production System: Beyond Large-Scale Production

Taiichi Ohno disseminated the concepts of takt time and continuous flow throughout Toyota, and over time, the principles of TPS became popularized through lean production. With them, so did takt time.

Learn more about this fascinating story in our article on The Origins of Takt Time.

How is Takt Time Calculated?

Let’s restate the takt time formula using generalized terms that bridge customer and manufacturing perspectives and that also draw from Taiichi Ohno’s above definition.

Generalized Terms

Required Quantity is the quantity of product that is needed over a specified time horizon, such as 1,260 pieces per week. This quantity can be derived purely from customer demand, or it can be adjusted to match what you actually plan to produce.

Planned Run Time is the amount of time that you have available to manufacture the part within that same time horizon, such as 32 hours (1,920 minutes) per week. This only includes time where the process is expected to be running (hence the name). In other words:

- It includes run time (actually running) and downtime (expected to be running)

- It excludes planned stop time (e.g., changeovers and planned maintenance) and time not scheduled for production (e.g., breaks and time between shifts).

Takt Time Calculation

Here is the same calculation as presented at the beginning of this article, restated with the new terms.

Takt Time can be calculated as Planned Run Time divided by Required Quantity.

If the above equation is rearranged and specified to use operable takt time (the pace you can actually achieve with your current process and equipment), it aligns with the production scheduling perspective.

Planned Run Time can be calculated as Operable Takt Time times Required Quantity.

If the equation is rearranged to calculate required quantity, it aligns with the plant floor operations perspective.

The equation for takt time is deceptively simple, which is why we provide lots of additional detail in our article about The Nuances of Calculating Takt Time.

What is Takt Time’s Relationship to Other Cycle-Based Metrics?

Cycle-based metrics can be split into two broad categories based on the time domain across which they are measured. The time domains are:

- Run Time

- Planned Run Time

Run Metrics

Run metrics are based on time when the process is actually running. The benchmark cycle metric is ideal cycle time, which is the theoretical fastest rate at which the process can run on a sustained basis. Ideal cycle time represents perfect production and is a key element of OEE (Overall Equipment Effectiveness).

Planned Run Metrics

Planned run metrics are based on time when the process is expected to be running. In addition to run time, this also includes downtime, which is time when the process should be running but is not. The benchmark cycle metric is operable takt time, which is the pace that the process can actually achieve on a sustained basis. It represents “real world” production and is a key element of Efficiency (how close the pace is to the plan).

A Loss-Based Time Model

The above model can be further extended to include all time and to function as a complete time model that spans OEE (overall equipment effectiveness) and TEEP (total effective equipment performance).

Schedule loss is in the realm of TEEP. The underlying calculation factor is Utilization.

All other losses are in the realm of OEE. The underlying calculation factors are Availability (Planned Stop Loss, Down Loss), Performance (Cycle Loss), and Quality (Quality Loss).

Fully productive time represents perfect production - pure productivity!

For a detailed exploration of cycle-based metrics, read our article on Comparing Takt Time to Other Cycle-Based Metrics.

How Does OEE Compare to Efficiency?

There are some very interesting comparisons to make between OEE (overall equipment effectiveness) and efficiency. Both are core metrics for manufacturing.

Exploring Perfection

First, let’s explore perfection. What does 100% mean when it comes to ideal cycle time (as applied to OEE) and takt time (as applied to efficiency)?

100% OEE

100% OEE represents perfect production. It is manufacturing as fast as possible as characterized by ideal cycle time (100% performance) with no defects (100% quality) and no planned or unplanned stops (100% availability).

100% Efficiency

100% efficiency represents manufacturing at the expected pace as characterized by takt time, with actual count (number of good pieces) equaling target count (a real-time target driven by takt time).

Cyclic Targets

The cyclic target for OEE is ideal cycle time. For efficiency, it is takt time. It is surprising how often ideal cycle time and takt time are conflated in real-world use. That can seriously throw off the accuracy of OEE scores, so it’s important to keep them straight. Let's explore the two metrics.

Ideal Cycle Time

Ideal cycle time represents the theoretical fastest cycle time that can be achieved for a given manufacturing process and includes no budgeted losses whatsoever. It is the benchmark cycle metric for OEE.

Takt Time

Takt time represents the cycle time that aligns demand to planned run time. It includes budgeted losses for slow cycles, small stops, defects, and downtime (all losses that occur when the manufacturing process is expected to be running).

Operator Perspective

In general, efficiency (and takt time) are much more meaningful to operators than OEE (and ideal cycle time). OEE is very abstract - you can’t look at an OEE score and immediately know if it is good or bad. It is always relative. Efficiency, on the other hand, has a very clear interpretation. If it is 100% or better, your operators are “winning the shift.”

| Category | OEE | Efficiency |

|---|---|---|

| Cycle-Based Metric | Ideal Cycle Time | Takt Time |

| Included Time | Run, Down, Planned Stop | Run, Down |

| Interpretation of 100% | Perfect Production | Attainable Production |

| Primary Audience | Managers | Operators |

| Short-Term Goal | Incremental Improvements | Win the Shift |

OEE and Efficiency are both key metrics for manufacturing, and it is interesting to contrast them.

Vorne XL - Takt Time and Much More

The Vorne XL Productivity Appliance™ is an advanced IIoT device that seamlessly integrates data capture, real-time production monitoring, a plant floor scoreboard, and rich reporting to rapidly and dramatically drive improvement at all levels of your manufacturing operation. Amongst its many features, it provides a real-time target and efficiency score for operators based on operable takt time, so they can “win the shift.” Of course, it also provides comprehensive OEE, TEEP, and Six Big Loss metrics for supervisors and managers.

Our most popular model is $4,190 and is available off-the-shelf for immediate delivery. We encourage all of our customers to start with a free 90-day trial. Book a one-on-one webinar and one of our product experts will be happy to explore your application.

XL includes 140+ metrics, 20+ data dimensions, unlimited users, unlimited reports, free software updates, free technical support, and an industry-leading 3-year warranty. There are over 30,000 XL installations across 45+ countries.

With XL you can easily:

- Track 140+ real-time and historical metrics

- Analyze metrics across 20+ data dimensions

- Empower your operators to “win the shift” with an integrated real-time scoreboard

- Provide immediate insights for managers with 50+ out-of-the-box reports

- Create unlimited custom reports to tailor data to your exact wants and needs

- Automatically push email alerts and reports to members of your team

- Automatically escalate alerts to call attention to urgent issues

Already have XL? Explore the latest features. Have questions? Contact us for assistance.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.