Implement OEE

Measuring OEE

This page is a “quick start guide” for measuring OEE. It provides a roadmap of key decisions and is organized in three parts:

- Define Project: things to decide before you start your OEE project

- Capture OEE Data: everything you need to calculate OEE

- Capture Detailed Loss Data: everything you need to calculate Availability, Performance, and Quality

Before starting this page, you should be familiar with the three OEE factors and how to calculate OEE.

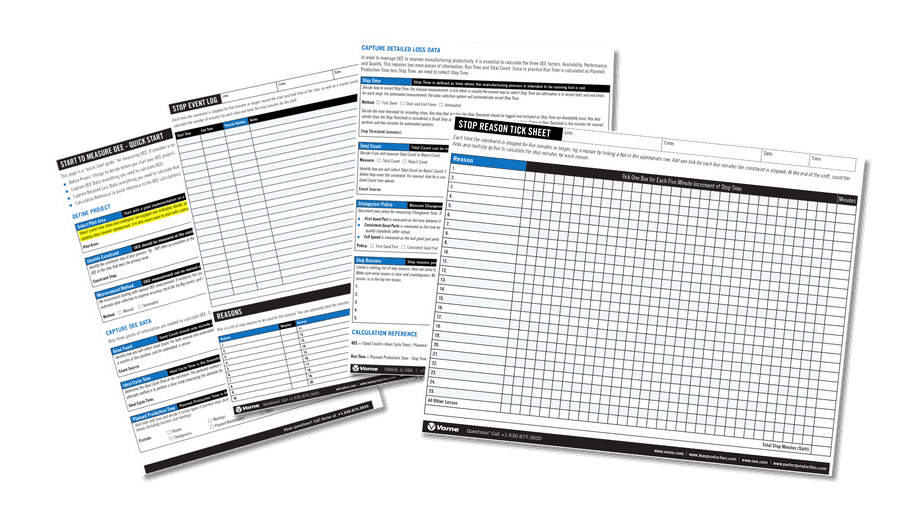

You can download a PDF form for organizing your OEE project.

Define Your Project

Select Pilot Area

When implementing any new initiative, it is usually best to start small and expand from a base of success. For OEE, that means starting with a pilot implementation on a single machine, cell, or line. Creating an OEE score at multiple points will give you conflicting information and potentially lead you to focus on less critical aspects of your process.

Select a pilot area where your employees are engaged and motivated; ideally an area where employees are interested in learning new things and applying ideas towards improvement. Preferably, select a pilot area that manufactures either one part or multiple parts with the same cycle time.

Identify Constraint

OEE should be measured at the constraint step of your process (sometimes referred to as the bottleneck). The constraint is the single step or machine that governs (i.e., limits) the throughput of the overall process. Improving the constraint will improve the overall process. If the constraint moves because you’ve improved the former constraint, move your OEE measurement to the new constraint and start again.

Identify the constraint step of your process.

Choose Measurement Method

OEE measurement can be manual or automated.

We recommend starting with manual OEE measurement. It reinforces the underlying concepts and provides a deeper understanding of OEE. Later, you may want to automate data collection to improve accuracy, track the Six Big Losses, and to generate top losses and other reports.

Capture OEE Data

Only three pieces of information are needed to calculate OEE: Good Count, Ideal Cycle Time, and Planned Production Time

Good Count

Good Count should only include parts that are defect-free the first time through the process. This is similar in concept to First Pass Yield, which defines good parts as units that pass through the manufacturing process the first time without needing rework.

Identify how you will collect Good Count. For manual measurement look for a counter immediately after the constraint that reliably counts good parts. For automated measurement look for a sensor immediately after the constraint that is triggered only for good parts.

Ideal Cycle Time

Ideal Cycle Time is the theoretical minimum time to produce one part (it is NOT a ‘budget’ or ‘standard’ time). It is important that Ideal Cycle Time be a true and honest measure of how fast the process can run, even if the process currently runs slower due to product, material, or equipment problems.

Determine the Ideal Cycle Time. The preferred method is to use Nameplate Capacity (the design capacity specified by the equipment builder). An alternate method is to perform a time study (measuring the absolute fastest speed the process can support).

Planned Production Time

Planned Production Time is the total time that the manufacturing process is scheduled for production. It is the yardstick against which Fully Productive Time is measured.

Start with shift time and decide if certain types of planned stops will be excluded (i.e., will not count against OEE). Most companies exclude only breaks (including lunches) and meetings.

Capture Detailed OEE Loss Data

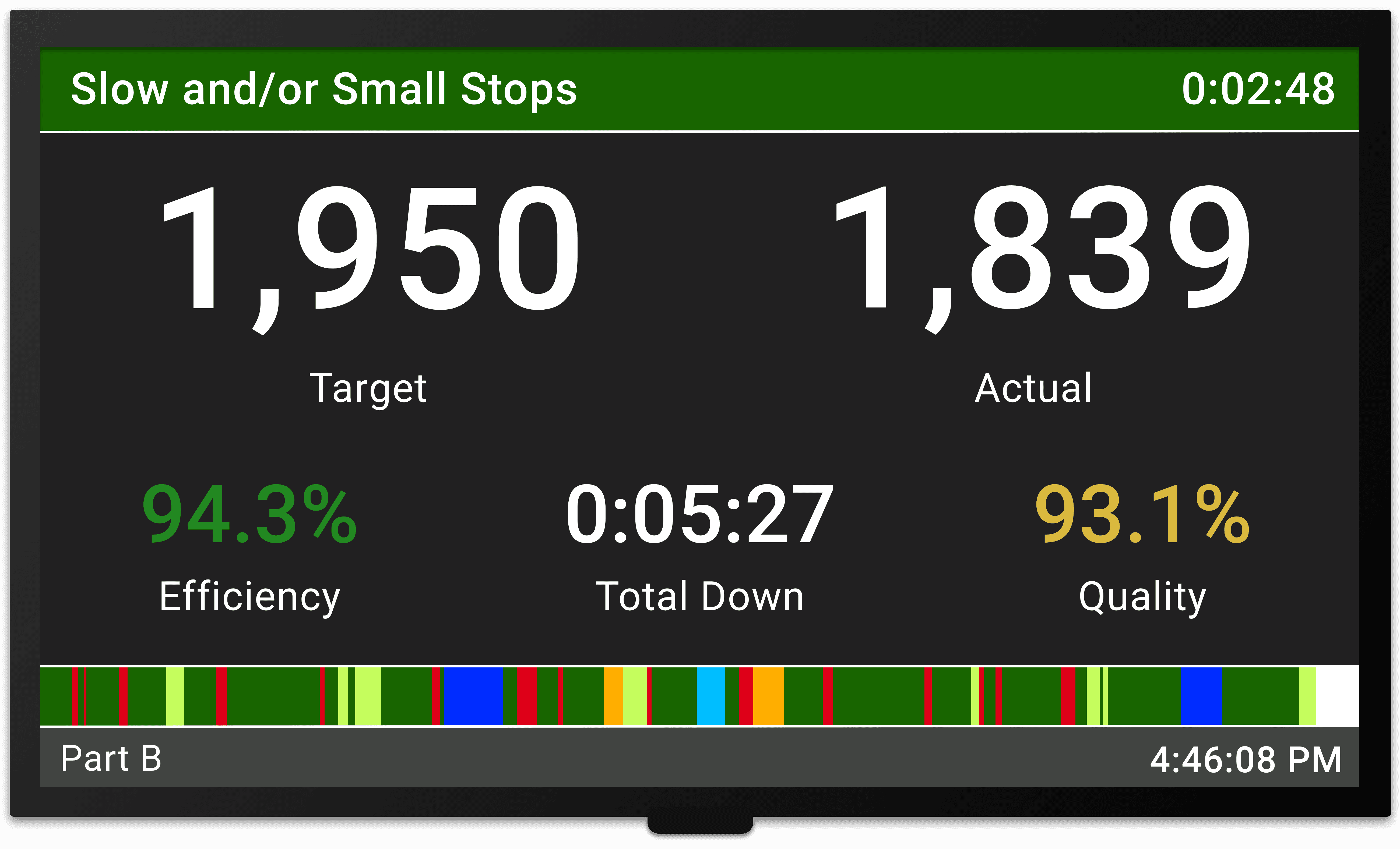

In order to leverage OEE to improve manufacturing productivity it is essential to calculate the three OEE factors: Availability, Performance, and Quality. This requires two more pieces of information: Run Time and Total Count. Since in practice Run Time is calculated as Planned Production Time less Stop Time, we need to collect Stop Time.

Stop Time

Stop Time is defined as all time where the manufacturing process was intended to be running but was not due to unplanned stops (e.g., breakdowns) or planned stops (e.g., changeovers).

Decide how to record stop time. For manual measurement a tick sheet is usually the easiest way to collect stop time (an alternative is to record start and end times for each stop). For automated measurement the data collection system will automatically record these times.

Decide the time threshold for recording stops. Any stop that reaches the threshold is recorded and is included as Stop Time (an Availability Loss). Any stop shorter than the threshold is considered a small stop (a Performance Loss) and is not recorded. A typical stop threshold is five minutes for manual systems and two minutes for automated systems.

Total Count

Total Count is required to measure OEE Quality. It can be measured directly, or Reject Count can be measured instead, and added to Good Count to calculate Total Count.

Decide if you will measure Total Count or Reject Count. For manual measurement of Total Count look for a counter that counts all parts going into the constraint. For automated measurement of Total Count look for a sensor before the constraint that is triggered for all parts. Reject Count is measured in the same place as Good Count (see above).

Changeover Policy

Measure changeover time consistently by defining the start and end points of each event.

Document a policy for measuring Changeover Time. Three common options are:

- First Good Part is measured as the time between the last good part produced (before setup) to the first good part produced (after setup).

- Consistent Good Parts is measured as the time between the last good part produced (before setup) to the first instance of consistently producing parts that meet quality standards (after setup).

- Full Speed is measured as the last good part produced at full speed (before setup) to the first good part produced at full speed (after setup).

Stop Reasons

Stop reasons provide insights as to why the process has stopped – especially for unplanned stops. They are an essential part of any manufacturing improvement program.

Create a starting list of stop reasons. Here are some tips:

- Start simple (10 reasons).

- Create a catch-all reason (All Other Losses).

- Make sure every reason is clear and unambiguous.

- Make sure every reason describes symptoms.

- Remove reasons that aren't regularly used.

- Add reasons if ‘All Other Losses’ is in the top ten losses.

Using OEE Data

Now you have a good understanding of how to define a project, how to gather the data you need in order to calculate OEE, and how to capture and calculate detailed loss data. You also have a roadmap of key decisions to make along the way. Use this information to start small and measure the OEE score in your pilot area, and then expand until you know the OEE of every line in your plant!

Once you have an accurate measure of your OEE score, you can expand your improvement journey by learning how to calculate TEEP, as well as how to use the information you have gathered to improve OEE.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.