Hidden Factory

What Is the Hidden Factory?

The hidden factory represents the untapped capacity of your manufacturing plant – the maximum amount of additional production that can be unlocked without capital investment. Fully utilizing your hidden factory means around-the-clock perfect production – manufacturing only good pieces, as fast as possible, with no downtime, every hour of every day.

The term “hidden factory” was popularized by Armand Feigenbaum in the late 1970’s. Feigenbaum’s concept of the hidden factory was primarily focused on quality, specifically the waste and costs caused by “bad work”, much of which is “hidden” below the surface of day-to-day operations.

Over time the hidden factory concept has broadened to include all waste in manufacturing. In this page we explore the hidden factory from that broader perspective, specifically focusing on the four areas of lost (or hidden) production potential from an equipment perspective:

- Schedule Loss (time where production could be running – but is not scheduled)

- Availability Loss (time where production should be running – but is not)

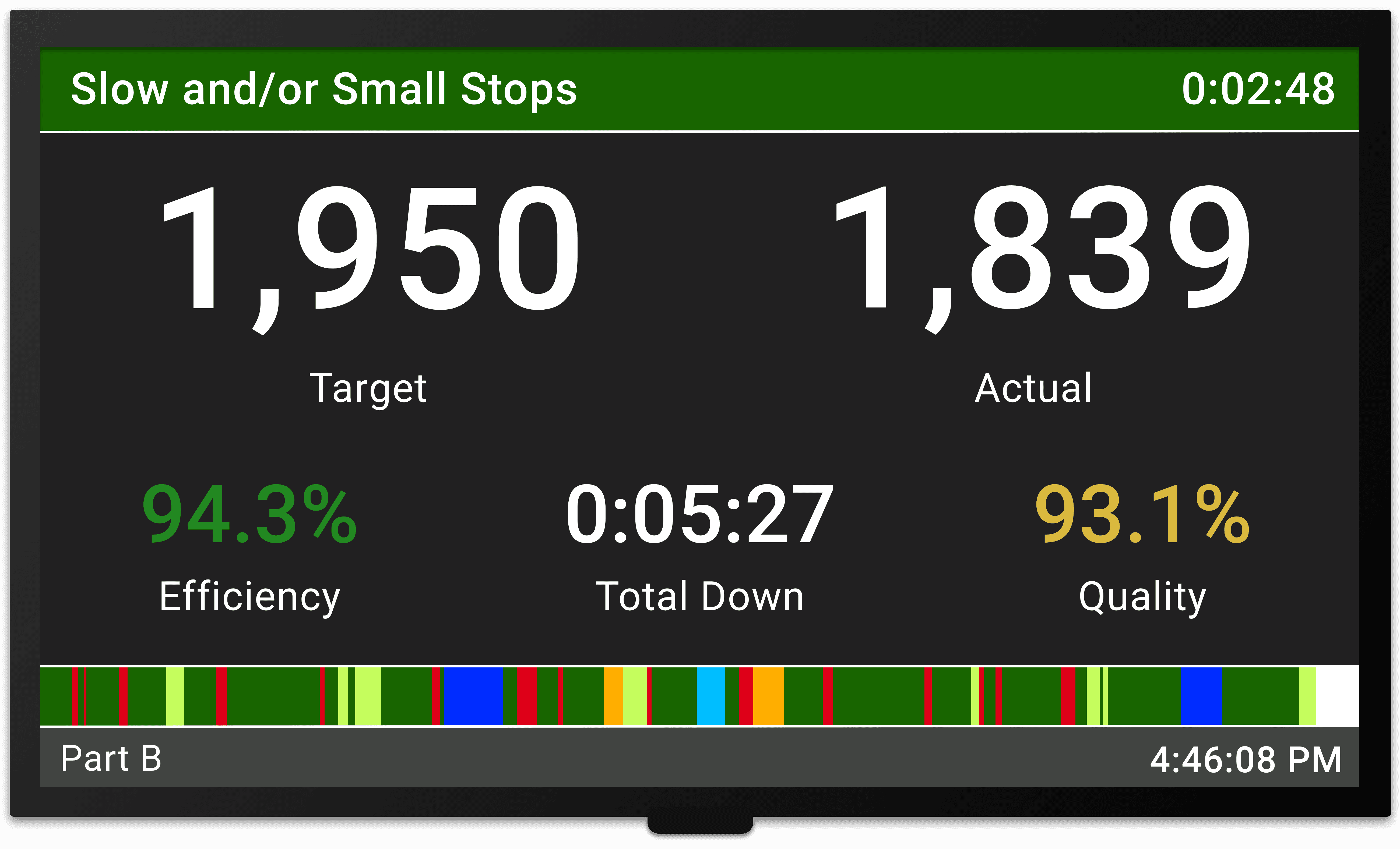

- Performance Loss (time where production is running – but not as fast as it should)

- Quality Loss (time where production is running – but one or more pieces are not good the first time through)

How Big Is Your Hidden Factory?

The untapped production potential in the hidden factory is typically very significant. Many manufacturers are surprised to learn that they have more capacity in their hidden factory than they are using in their actual factory.

The fastest way to discover how much potential is in your hidden factory is to perform two very simple calculations:

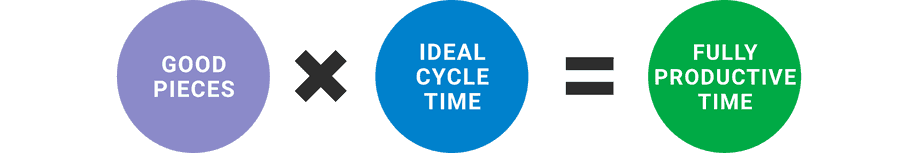

First, calculate your Fully Productive Time by multiplying Good Pieces by Ideal Cycle Time. Fully Productive Time represents how close you are to perfect production - manufacturing only good parts, as fast as possible, with no downtime.

- Good Pieces are pieces that pass through the manufacturing process the first time without needing any rework.

- Ideal Cycle Time is the theoretically fastest cycle time your process can achieve under optimal conditions.

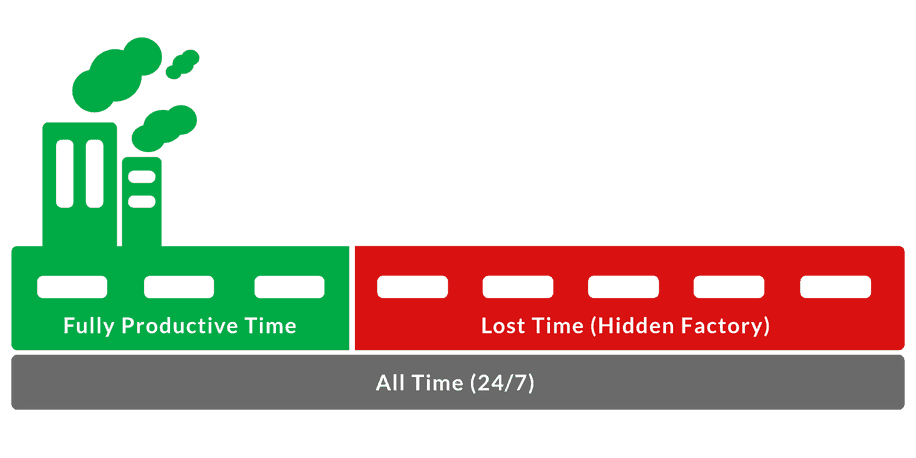

Second, calculate your Hidden Factory by subtracting Fully Productive Time from All Time (24/7). This Hidden Factory time represents the untapped capacity of your manufacturing plant.

The hidden factory takes into account all four types of lost time described earlier: Schedule Loss, Availability Loss, Performance Loss, and Quality Loss. More on that in the next section.

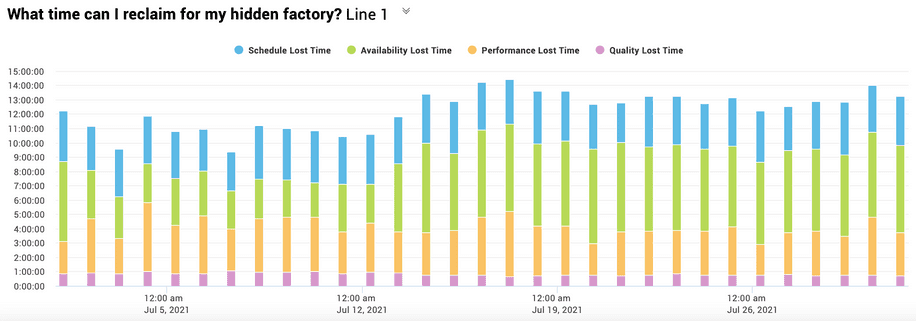

Where Is Your Hidden Factory?

To unlock the potential of your hidden factory, it’s important to understand your losses – where they occur in production. First, make sure you are measuring losses that affect your manufacturing constraint. Then understand how each loss factor impacts your hidden factory. Some important tools are:

- TEEP (identifies losses due to time that is not scheduled for production)

- OEE (identifies losses during scheduled production time)

- Six Big Losses (provides more detail on losses during scheduled production time)

The following table shows the four major loss factors as described earlier, their impact on the hidden factory, and the associated Six Big Losses.

| Loss Factor | Impact on Hidden Factory | Six Big Losses |

|---|---|---|

| Schedule Loss | Time where production could be running but is not scheduled.

| Does Not Apply |

| Availability Loss | Time where production should be running but is not.

|

|

| Performance Loss | Time where production is running but not as fast as it should.

|

|

| Quality Loss | Time where production is running but one or more pieces are defective the first time through.

|

|

Benefits of Tapping into Your Hidden Factory

The most significant benefit of tapping into your hidden factory is that you can increase throughput without additional capital expenditures. Simply put – making more with what you already have. When you increase throughput, this enables three big benefits:

- Decreased Conversion Cost: Fixed costs are spread over more output (increasing profitability).

- Increased Flexibility: Shorter production runs are possible, improving lead times and reducing inventory.

- Deferred Spend: Increase throughput on existing assets and defer spending on new equipment or facilities.

At the factory-floor level, tapping into your hidden factory can decrease overtime or eliminate outsourced production. This benefit, though, is more in the realm of traditional OEE. What is specifically unique about the hidden factory is that in addition to OEE Losses it also takes into account Schedule Loss, which makes it an excellent tool for capacity planning:

- Improved Capacity Planning: Understand and take into account the untapped capacity of your manufacturing plant when doing long-term capacity planning.

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.