HOW TO ADDRESS THE SIX BIG LOSSES

Overview

The Six Big Losses provide an equipment-based perspective on lost production time. Just like OEE, the Six Big Losses have their roots in TPM (Total Productive Maintenance). In fact, one of the goals of TPM is to eliminate the Six Big Losses.

One of the most effective paths to improving OEE is through the Six Big Losses. Let’s spend a little time exploring ways to leverage the Six Big Losses as part of your improvement program.

Equipment Failure

Overview

Addressing equipment failure (i.e., Unplanned Stops) is critical to improving OEE. For most companies, Unplanned Stop time is the single largest source of lost production time.

A prerequisite to successfully addressing Unplanned Stops is to understand the nature of the problem. In other words, attribute each instance of an Unplanned Stop to a reason for the loss – through reason codes. This will enable you to apply Root Cause Analysis to your top losses.

Tips on Using Reason Codes

Here are some tips for effective use of reason codes:

- Start simple, with no more than 25 reasons.

- Create a catch-all reason for ‘All Other Losses’.

- Make sure every reason is clear and unambiguous when compared with other reasons.

- Make sure every reason describes symptoms, as opposed to attempting to diagnose root causes.

- Remove reasons that aren't regularly used.

- Add reasons, as needed, to ensure that ‘All Other Losses’ is not in the top ten losses.

Focused Improvement

A highly effective process for reducing Unplanned Stop time is a focused improvement activity (sometimes called a kaizen blitz).

In a focused improvement activity a cross-functional team selects one type of loss to address (often from a top losses report). The team then applies OEE loss analysis via a Root Cause Analysis or a 5 Why Analysis to identify potential causes and fixes.

Once an issue is fixed, it is important to update related standardized work procedures to lock-in improvements (and avoid “same problem/different day” recurrences).

Setup and Adjustments

Another major source of lost production time for many manufacturers is setups (also called Changeovers or Make Ready). We recommend expanding the definition of Setup and Adjustments to cover all planned stops (e.g., including preventative maintenance) that occur during planned production time. After all, any time that could productively be used for manufacturing is an opportunity for improvement.

Establishing a Consistent Policy

A good starting point for Setup and Adjustments is to make sure you are consistent in how you measure Setup Time (to ensure you have an accurate information foundation). For example, your policy might be:

- Setup Time is measured as the time between the last good part produced (before Setup) to the first good part produced (after Setup).

Some companies prefer to include startup or warmup time as part of Setup, in which case your policy might be:

- Setup Time is measured as the time between the last good part produced (before Setup) to the first instance of consistently producing parts that meet quality standards (after Setup).

Either way is fine – just make sure to document your policy and apply it consistently.

SMED (Single-Minute Exchange of Die)

A well-established and highly effective way to address setup loss is SMED (Single-Minute Exchange of Die).

SMED is a collection of techniques for dramatically reducing the time it takes to complete a setup. The goal of SMED is to reduce setup times to less than 10 minutes (i.e., single-digit minutes). Each element of the setup is analyzed to see if it can be:

- Separated (moved, as is, before or after the setup)

- Converted (modified, so it can be moved before or after the setup)

- Streamlined (modified to be faster)

Here are several examples of changes that are often made as part of a SMED program:

- Put together setup carts with all tools and supplies necessary to complete the setup.

- Prepare parts in advance (e.g., preheat dies in advance of the setup).

- Use pinned or marked settings so that coarse equipment adjustments are no longer necessary.

- Eliminate bolts (e.g., use quick release mechanisms or other types of functional clamps).

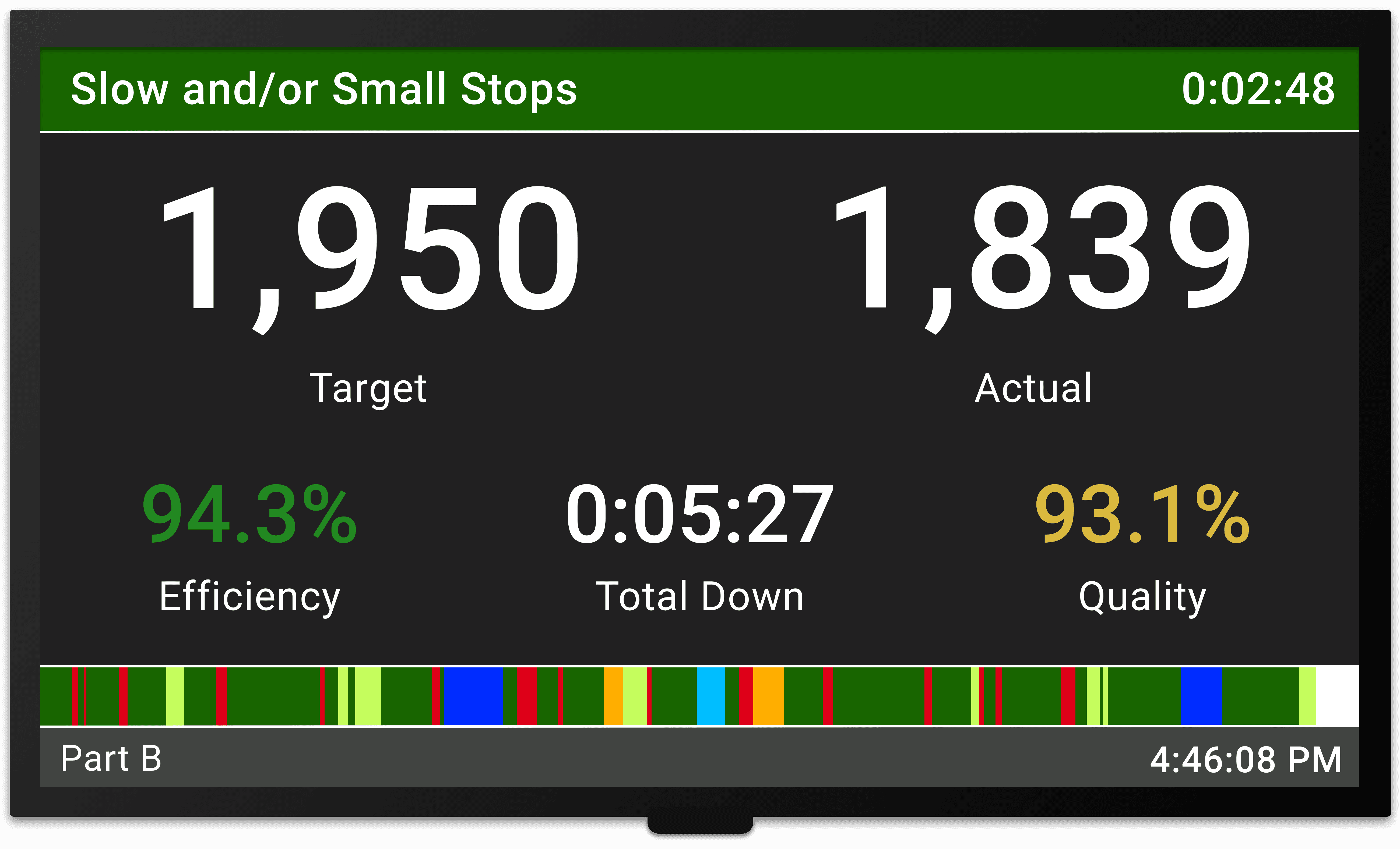

Idling and Minor Stops/Reduced Speed

While it is fairly easy to manually calculate performance loss, breaking it down into the underlying Six Big Losses (Idling and Minor Stops and Reduced Speed) is considerably more difficult. For most manufacturing processes, accurate and detailed measurement requires an automated system that measures individual cycles.

The root causes of Idling and Minor Stops and Reduced Speed are typically quite different, which is why they are independent elements of Six Big Loss analysis. This section does not make a distinction since many manufacturing operations do not have the capability of differentiating between Idling and Minor Stops (small stops) and Reduced Speed (slow cycles).

Ideal Cycle Time

A good starting point for addressing performance loss is to validate ideal cycle times (to ensure you have an accurate information foundation).

Ideal cycle times should be available for every part and should represent the maximum theoretical speed of the equipment for that part (NOT ‘budget’ or ‘standard’ speeds that are slower than the maximum).

If your OEE Performance is ever higher than 100%, carefully review the ideal cycle time. You are likely to find that it is too high (and masking lost production time).

Patterns

Look for patterns of significant performance loss (i.e., an unusual number of slow cycles or small stops). For example, performance loss may be more prevalent:

- After a part or material change

- After an environmental change

- During a specific shift

- Over time (a consistent degradation over time)

Once your team identifies a pattern apply Root Cause Analysis or 5 Why Analysis to identify potential causes and fixes.

Once a problem is fixed, it is important to update related standardized work procedures to lock-in improvements (and to avoid “same problem/different day” recurrences).

For high-speed equipment it may be worth purchasing a high-speed camera to capture cycles with enough resolution to see potential problems that would otherwise be invisible.

Countermeasures

Some common countermeasures for performance loss are:

- Schedule proactive maintenance and lubrication activities.

- Introduce a 5S program to improve the condition of equipment.

- Train operators on standardized work procedures.

- Tighten material quality standards.

- Improve the precision of equipment set-points.

Process Defects/Reduced Yield

Process Defects and Reduced Yield occur during different stages of production, which is why they are independent elements of the Six Big Losses:

- Process Defects (also known as production rejects) occur during stable production.

- Reduced Yield (also known as startup rejects) occurs during startup and is often a result of setups and warmup periods.

Note that the Six Big Losses capture lost time. They do not capture lost material when product is scrapped.

Reduce Variation

One of the most effective countermeasures to quality problems is to reduce variation (one of the central goals of Six Sigma). Variation is one of the reasons that there is often a higher rate of defects during startup – there is more variation in the process.

A very effective way to reduce variation is to pay close attention to equipment settings and materials:

- Equipment Settings (define and implement more precise equipment settings, in some cases on a part-by-part basis)

- Materials (run material tests on equipment to determine if tightening tolerances positively impacts quality)

These same countermeasures are also often effective for performance loss (e.g., resulting in fewer jams).

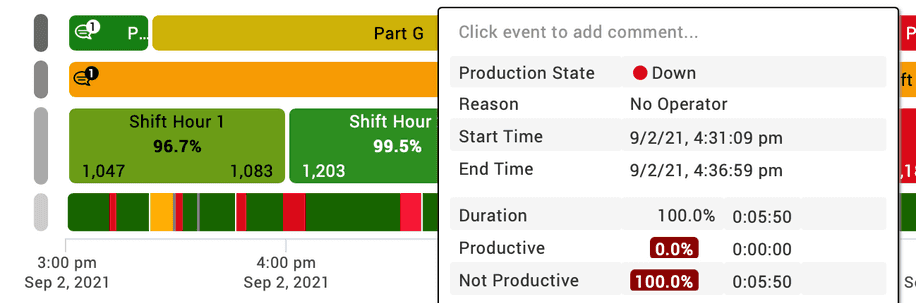

SIC (Short Interval Control)

SIC (Short Interval Control) is a factory-floor process for driving production improvements during the shift. Each shift is split into short intervals of time (typically two to four hours), within which plant-floor employees use data to identify and implement improvement actions. These improvement actions may be countermeasures to ongoing or emerging problems, or they may be actions to improve existing production.

SIC can be very effective for all types of losses, because it dramatically shortens the time between a problem occurring and a countermeasure being proposed.

The Role of the Six Big Losses in TPM

Even a fairly simple TPM (Total Productive Maintenance) program can have a significant positive impact on the Six Big Losses. Taking a “going back to basics” philosophy, when TPM was first introduced in Japan, many companies achieved significant improvements in OEE through various combinations of:

- Measuring OEE and Six Big Losses: to track improvement

- Autonomous Maintenance: proactive maintenance by operators

- Preventive Maintenance: proactive maintenance by maintenance personnel

- Standardized Work: capturing and following best practices

- Error Proofing: quality by design

- Training: enhancing staff capability

WHAT YOU SHOULD DO NEXT...

1. Learn more about how our product, Vorne XL, can help you eliminate waste and significantly improve OEE.

Vorne XL is the simplest and fastest way to monitor and improve production. It's a one-time cost and takes just a day to install. And you can try it completely free for 90 days.

Learn More2. Download our FREE package of tools to supercharge your manufacturing productivity

The package includes leadership lessons, training guides, meeting and report templates, summaries of key concepts, project organizers, and more. You'll also receive our monthly newsletter for free. Unsubscribe at any time.

DOWNLOAD FREE LEAN TOOLS3. Sign up for our monthly newsletter

Get free monthly updates with proven methods for improving our manufacturing productivity. Unsubscribe at any time.